5000 series aluminum alloys-best 5000 series aluminum alloys manufacture in China

5000 series aluminum wrought alloys

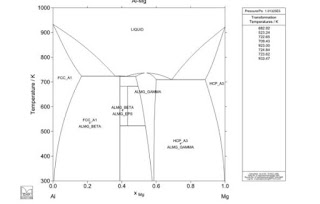

Aluminium alloys 5000 series refers to the system Al-Mg. The alloys of this system (Mg < 10%) refer to the group of non-thermally hardened. The hardening is achieved by means of cold plastical deformation. The properties of these alloys are achieved by Mg content increase in the supersaturated solid solution. Main representatives of this series of alloys are: 5052, 5182, 5754, 5083.Typical tensile strength range for such alloys is: 125 – 350 MPa.

5000 series aluminum alloys Properties

- High strength;

- High corrosion resistance;

- Good weldability;

- Good resistance to low temperatures close to the absolute zero level;

- Good resistance to HNO3, diluted H2SO4, H3PO4, as well as SO2 containing atmospheres;

- Good ductility;

- Low density.

When Mg content exceeds 3% corrosion resistivity is reduced depending on the application and temperature of operation (more than 1000С).

Group of alloys Al-Mg are characterized by good corrosion resistance (in general under stress and other means of corrosions). It is necessary to note their good corrosion resistance in the sea water. High strength of Mg alloys is achieved by a thin oxide film that appears on the surface.

For additional information, see https://www.alufoil.cn/

5000 Aluminum Sheet Specifications

- Sheets thickness: 0.15-2.0mm

- Plate thickness: 2.0mm-250mm

- Temper: Soft and Variety Hard temper (O-H116) (T2-T6)

- Cusotom requirements are acceptable

5000 series aluminum alloys Sphere of application

- Manufacturing of tanks under pressure (5052, 5754, 5083, 5154, 5454, 5456);

- Manufacturing of automotive and rail road volumes for bulk materials (5052, 5083, 5154, 5456);

- Manufacturing of automobiles and sea vessels (5005, 5042, 5083, 5182, 5454, 5745, 5754, 5052, 5456);

- Chemical industry (5083,5254);

- Manufacturing of lids and keys for cans (5052, 5182);

- Used as armor protection for military industry (5083, 5456);

- Manufacturing of architectural and building assemblies (5005, 5052, 5252, 5457);

- Household goods, cookware (5005).

Dissolution of alloying elements and their influence on the alloys properties

In order to improve the strength and corrosion resistance characteristics Mn and Cr are added. As strengthening agents in small portions Sc, Zr are used.Mg content in the alloy is 0 to 37,5% which is eutectics. Eutectics exists at the temperature equal to 449 °С and Mg content 34,5% . Dissolution of Mg at this temperature is maximum and equals to 17,4% (in some sources 16,5%). At the temperature 300°С in ?-solid solution only 6,7 % Mg can be dissolved; at 100°С - 1,9% Mg. Mg that was not dissolved remains in the form of ?-phase (Al3Mg2).

Implementation of 0,5…0,7 % Mg into aluminium increases dramatically the ability of alloy to hot cracks formation (~65 %). Further on this characteristics (K) is reduced and stabilized at a level of 30% with 6…7% Mg.

5000 series aluminum alloys Manufacturing peculiarities

- Mg strengthens aluminium. Each per cent (by mass) of Mg increases aluminium strength by 30 Mpa with the simultaneous reduction of absolute weight. But the sphere of application for wrought alloys was limited by the Mg content at 6%. Alloys with higher Mg content are usually in the group of casting alloys. Though they are characterized by high strength, good corrosion resistance, their level of ductility did not allow to apply the process of plastical deformation to manufacture sheets and shaped products for further shape change during the process of sheet stamping.After deep examination of the alloying additions influence at the moment there is a way for alloys manufacturing at Mg content more than 10% with improved strength characteristics without the loss of ductile characteristics.

- In order to improve the structural homogeneity of the ingots it is required to add Ti into the holding furnace as well as during casting process in the shape of rods Al-Ti-B.

- 5000 series alloys together with other multicomponent alloys tend to cracks formation and structural inhomogeneity during products manufacturing. To eliminate the defects the same ways as for 7000 series of alloys are used.

- Products made of 5000 series is pulled and rolled to 1-3 mm thickness. In order to eliminate the penalty during ready made products, the filtration and degassing process must be implemented at the casting stage.

5000 series aluminum alloys Related products:

- 5052 Aluminum Sheet

- 5083 Aluminum Sheet

- 5754 Aluminum Sheet

- 5052 aluminum plate

- 5083 aluminum plate

- 5154 aluminum plate

- 5182 aluminum plate

- 5754 diamond aluminum plate

hwalufoil-leo

评论

发表评论