3000 series aluminum alloys-best 3000 series aluminum alloys manufacture in China

3003 series aluminum is the most widely used of all aluminum alloys. Essentially, it is technically pure aluminum with addition of manganese, which increases its strength by about 20 % compared with the 1000 series aluminum . This series of alloys hardened only by cold plastic deformation.

3000 series alloys is an alloy of Al-Mn. The manganese content can reach 1.5 %.

As an improvement in the characteristics alloying elements Mn , and Cu are used. To obtain a homogeneous structure of semi-products and for good plastic characteristics 3000 series is alloyed with Ti.

3000 series aluminum Features

- Alloy:3003, 3004, 3005, 3105

- Temper: H14, H16, H18, H22, H24, H26, O

- Thickness(mm):0.25-10

- Width(mm):800-2200

This series aluminum sheet is anticorrosive and its production technology is good.

The main ingredient in it is manganese element and the content is between 1.0% and 1.5%.

3000 series aluminum Properties

- Tensile strength: 110 - 280 MPa (adding 1% of the melt increases the tensile strength of the finished product by 10-15 MPa);

- Good formability;

- Excellent corrosion resistance;

- High plasticity;

- Good weldability.

For additional information, see https://www.alufoil.cn/

3000 series aluminum Field of applications

- Production of beverage cans (3004, 3104);

- Production of automotive radiators (3002);

- Heat exchangers and radiators of vehicles and power plants (3003);

- Manufacture of chemical equipment and utensils (3003);

- Roofing and siding (3105).

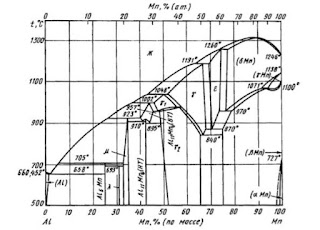

The solubility of alloying elements and their influence on the properties of the alloy

Manganese can hardly be dissoluted in aluminum and forms a chemical compound of MnAl6. This compound makes eutectic with aluminum, containing 1,95% Mn, Al- rest. The solubility of manganese in aluminum at the eutectic temperature, is 1.82 % at 500 °C - 0.36 %. With further decreasing temperature the solubility of manganese changes a little, so the alloy is not hardened with heat treatment (hardening - aging). Impurities of iron and silicon reduce the solubility of manganese in aluminum, iron in the alloy forms with manganese and aluminum coarse crystals ternary phase FeMnAl6, reducing the ductility of the alloy. In the presence of silicon and iron alloy forms a four- phase ?-Al (MnFe) Si, which upon solidification does not create coarse forms and up to a certain limit the content (0,5% Fe, 0,4% Si in the alloy is 1.2 % Al Mn) helps even to increase in the mechanical properties of Al-Mn alloys. Also, manganese reduces the recrystallization process, increasing its temperature.3000 series aluminum alloys Statechar of Al-Mn

3000 series aluminum alloys Features of production

1、During the production of alloys 3000 series cracking is the most common feature. Hot brittleness is caused by the formation of complex insoluble intermetallic phases along the grain boundaries.Below is a graph showing the sensitivity of the alloy to hot cracking as compared with the content of alloying elements. Critical range of silicon and magnesium in the 2000 and 3000 series aluminum is shown in red.

2、It is necessary to obtain an equiaxed grain structure ingots for quality products. The type and size of the grains formed is determined by the alloy composition, the crystallization rate, and by usage of the alloying additions ( grain refiners ) containing intermetallic particles which provide centers of crystallization. Fine grain size minimizes shrinkage, hot cracking and porosity.

All aluminum alloys solidify with a fully equiaxed , fine-grained structure with grain refiners. The most commonly used ligatures system Al-Ti-B. Modifiers based on Al-Ti generally contain from 3 to 10 % Ti. The same range of concentrations of titanium used in Al-Ti-B to a boron content from 0.2 to 1%, and the ratio Ti / B is in the range of from 5 to 50.

Under normal conditions of crystallization, covering the entire range of industrial processes casting, aluminum alloys without grain refiners demonstrate coarse columnar and / or coarse equiaxed structure.

All aluminum alloys solidify with a fully equiaxed, fine-grained structure with grain refiners. The most commonly used alloying additions belong to system Al-Ti-B. Modifiers based on Al-Ti generally contain from 3 to 10 % Ti. The same range of titanium concentration is used in Al-Ti-B to a boron content from 0.2 to 1%, and the ratio Ti / B is in the range of from 5 to 50.

To be effective, grain grinders should be controlled by the number of aluminides and borides, their shape, size and distribution of grain nucleation. Rod-shaped ligature, designed for continuous processing operations in primary aluminum is produced in the form of coils 200 kg each.

3、The thickness of the foil in the form of semi-finished products for the production of beverage cans is 250 - 350 microns. The final thickness of the wall - 100 - 150 microns depending on the volume of the can. In this connection, for the production of alloys 3000 series fine filters are used in conjunction with metal furnace refining installations.

评论

发表评论